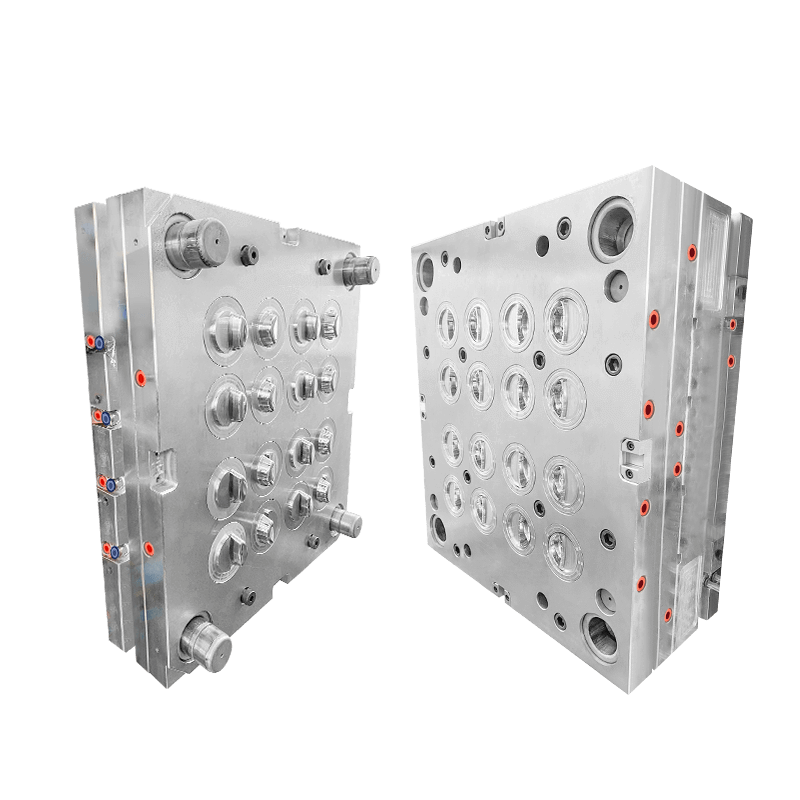

High Quality Liquid Cap Mould Quotes - 16 Cavities Cookie Cover Mould – Aisen Detail:

Mold Life Time: 3-5 million shots

Surface Request: High polish, High Gloss or Texture

Core& Cavity: H13/S136/2083/2344/2085/ASSAB STAVAX ESR

Mold Base: P20/ 4CR13/2085/2316

Runner System: Cold runner/Chinese brand/ YUDO/MASTER/HUSKY

Customization: Available

Mould Design: UG, CAD/CAM, PROE etc

mould processing: CNC, High speed carved, Digital controller lathe etc

mould gate type: Pin gate, Submarine gate, Valve gate etc

mould ejector type: Unscrew by motor, stripper plate, ejector sleeve, ejector pin

Package Details: Export Standard Seaworthy packing.

Place of Origin: Taizhou, China

We pay great attention to mold quality:

1.Ensure the authenticity of the mold material: We will provide the original certificate of country of origin of the material and the original heat proof of the material. The material with high purity, good toughness and good polishability is preferred. Germany’s steel and Sweden’s ASSAB materials are in the form of direct sales from the original factory, preventing material counterfeiting.

2.Advanced mould design: Cooperate with high-end mold companies all over the world, and have advanced mold design concepts and advanced mold structure design drawings.

3.Hot runner structure for easy replacement: The structure design of the nozzle is similar to that of the hot nozzle of the PET preform mold Replacing parts can be done on the machine.

FAQ:

We always face the flashes problem, is this the mold problem or injection problem?

First, please check the mould part fitment, if it is well, then please adjust the injection data. There will be several possibility to cause this problem: (1)Too high injection pressure, (2) Insufficient clamping force, (3) Too much material supply, (4) High resin temperature, (5) Too long injection pressure

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for High Quality Liquid Cap Mould Quotes - 16 Cavities Cookie Cover Mould – Aisen , The product will supply to all over the world, such as: Italy, Egypt, Luxembourg, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.