Quality is the life of AISEN. AISEN's excellent quality control system and product quality standards can help customers and his processing plants save costs and time.

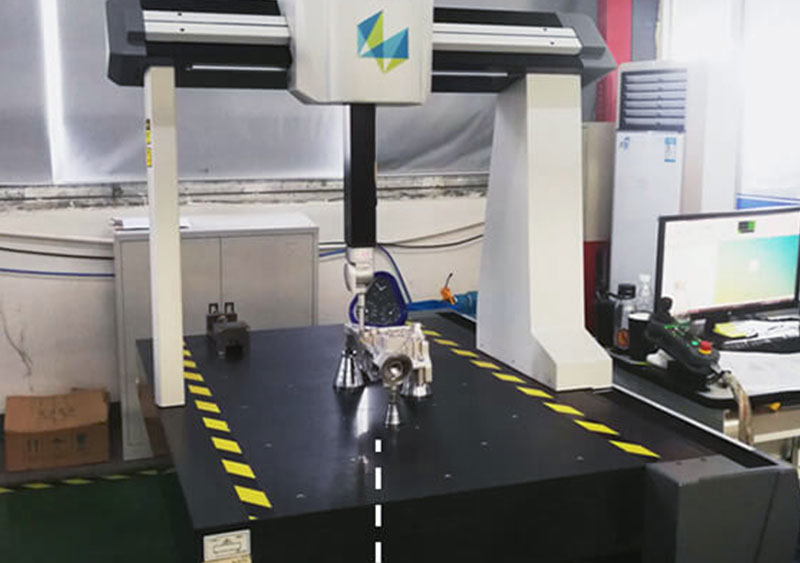

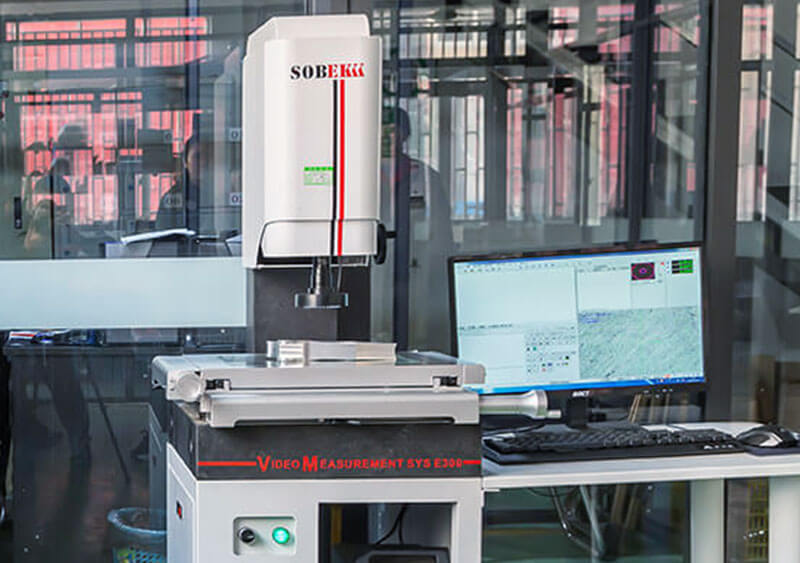

■ Strict dimensional inspection and Accurate analysis of samples

The quality inspection team owned by AISEN, from the first trial of plastic bottle caps to the analysis of trial samples, must go through very strict dimensional inspection and quality control to ensure that the produced molds can ultimately meet customer production and injection molding. All requirements for molding.

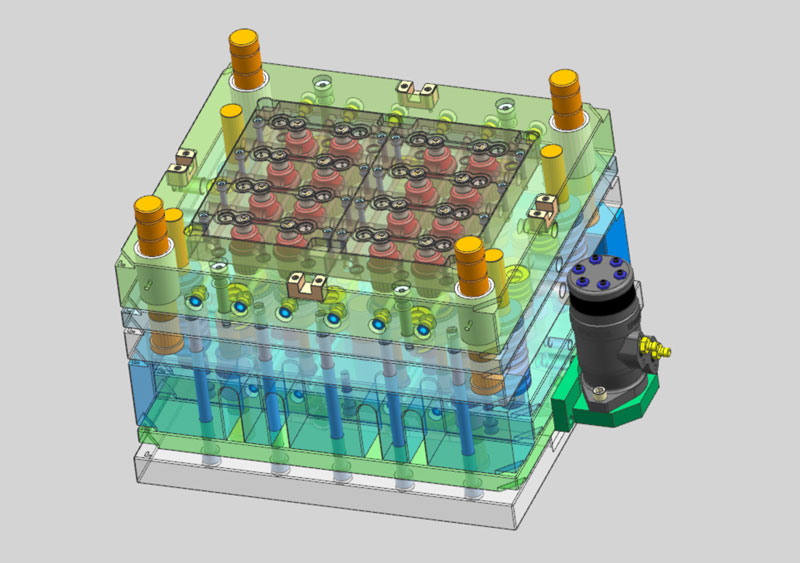

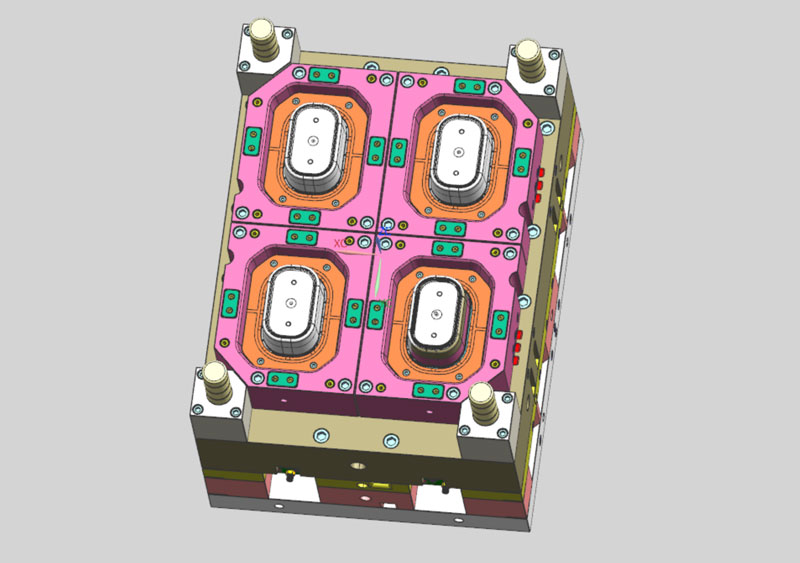

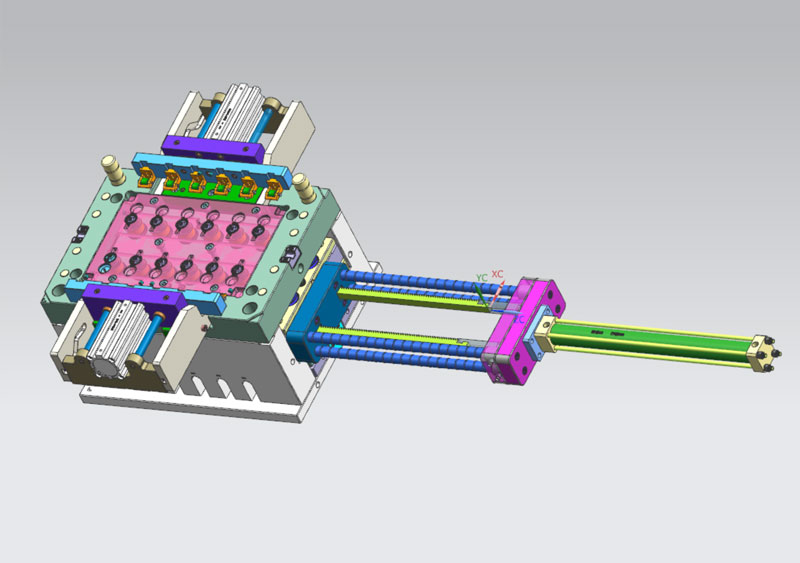

■ 20 years' experienced engineers design precise drawing with pretty good cooling system

■ High-precision processing techniques

A good set of plastic bottle cap molds stems from the quality concept of AISEN people for excellence.

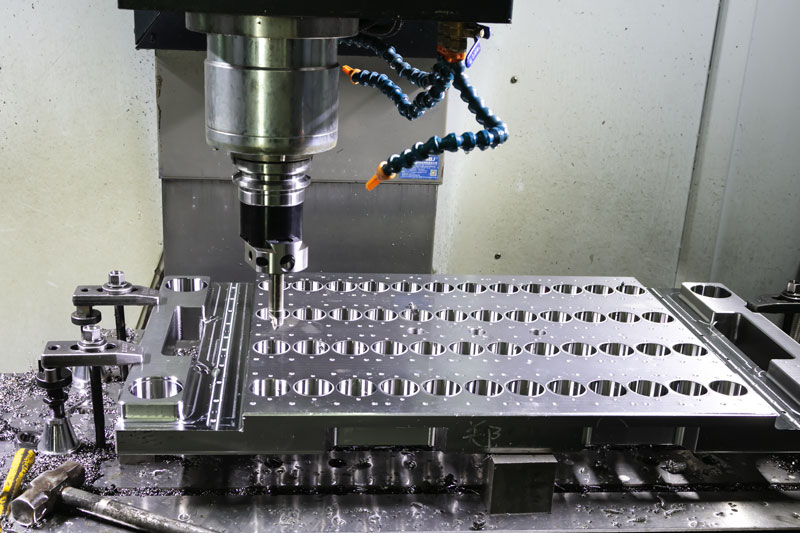

(1) High-speed CNC machine

Stable to achieve "0.1μm feed, 1μm cutting, nm level surface roughness"

(2) Multiple CNC machining centers with three-axis and four-axis linkage:

Stable to process the complex mould parts, to meet the requirements of precision mold processing, can be stable to achieve 10-30μm machining accuracy.

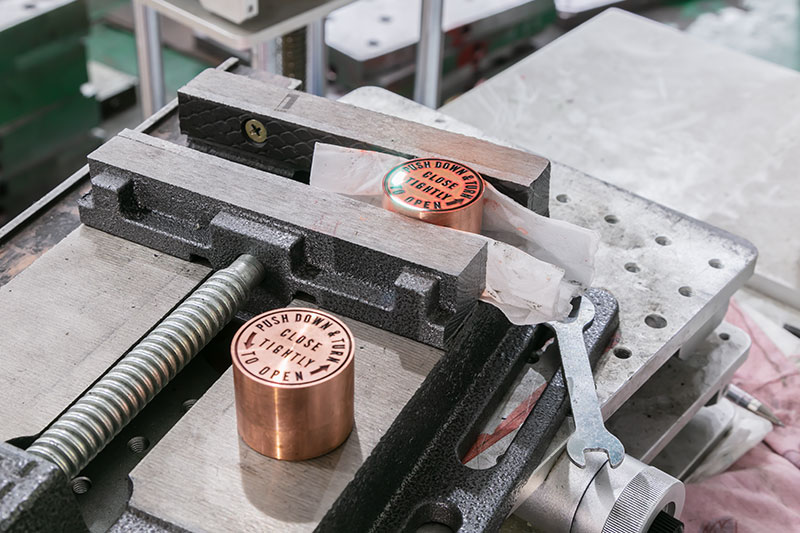

(3) Mirror Spark machine

Expert system, equipped with a powerful processing technology database, to achieve high accuracy (repeat positioning accuracy ≤2μm), high efficiency (≥500mm/min), the best surface finish (RA ≤0.1μm), save the manual polishing process, improve the surface of mould parts

■ High-precision processing techniques

Choosing a qualified hot runner system can ensure the balanced and stable injection of all gates of the mold, so as to produce better plastic bottle caps. Taking into account the convenient replacement of mold-related accessories in the later period, We can provide various brands of hot runners for customers to choose.